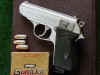

The Walther PPK

photos by Mike Cumpston

edited by John Dunn

Click on any thumb-nailed image and a larger photo opens in a new window.

The PPK came about in 1932 as a downsized version of the German Police Pistol (PP), which had seen instant and widespread acceptance immediately upon its introduction in 1928. The K in the title stands for “Short” and it is noteworthy that it is shorter than the original not only in overall length, but in the grip department as well. The model PP has a full grip frame while the smaller PPK eliminates the back strap leaving the hammer spring to be enclosed by the wrap-around grip panel. The grip is also shorter on the vertical plane reducing the magazine capacity to six.

The PPK remains in production under the joint auspices of Walther and Smith and Wesson and new purchasers are frequently surprised to see the S&W address line on the front right of the slide. It is probably the only true twentieth century classic auto pistol not designed by John M. Browning that has remained in production since first introduction. Another important distinction is the Walther-type action system that was the single standard for double-action self-loading pistols until recent years.

The "mouse gun"

When well constructed and maintained, it is a useful enough hideout gun to justify its existence and then, of course, there’s James Bond. Bond was the fictional celeb that introduced the PPK to the popular culture while the real-life celebrity PPK owner was none other than Adolph Hitler. Yep. Der Fuhrer owned not one but two PPKs. One was a richly engraved example in .25 ACP (6.35 Browning) and the other was a plainer example in the ubiquitous 7.65/. 32 ACP. The latter PPK seems to have figured in the demise of Mr. and Mrs. Hitler to forestall the unpleasant side effects of sodium cyanide. Not too many aficionados of the PPK brag that they have a pistol just like the one carried and used by the architect of the Third Reich but quite a few are proud to claim material kinship with the profligate 007.

The PPK is 6.1” long, 3.9” tall with the flat magazine in place (it also comes with a magazine with a finger extension on the base plate). Unloaded weight is 21 oz. While many modern service caliber “pocket rockets” now compete with these dimensions, few if any can approach the flatness of the pistol as it measures in the mid -. 90” range across the slide and grips. This alone is enough to tip the scales in its favor for many perspective carriers. After the Gun Control Act of 1968, the PPK became temporarily unavailable because of the size criteria. The German Walther company mated the PPK barrel and slide with the larger grip frame of the PP resulting in the importable PPKS. Eventually, the traditionally sized PPK became a domestic product under Walther USA but the desirability of the larger grip frame and additional magazine capacity have kept the PPKS in production.

Historically available in .22 LR, 25 ACP .32 ACP and 380 ACP, The Current Stainless American/Walther/Smith and Wesson numbers come in the latter two calibers. The .32 has been considered an adequate police round in Europe and Asia while the .380, at least until recently, was considered the bare minimum defensive round in America. Recent .32 ACP loads have changed this to some extent but the .380 still has a clear advantage in the realm of kinetic energy. Most ammunition companies provide ball ammunition in the 95-Grain weight range and have also developed reliable functioning 85-90 grain Jacketed Hollow Point loads that really expand. In my PPK American, ball ammunition from PMC and CCI (Blazer) clocks circa 980 fps while the 90-Grain Speer Gold Dot is good for 1060 fps or thereabout. Corbon 90 grain JHPs seem to lead the pack in regard to velocity/energy with one batch I checked doing 1140 fps and another lot clicking off 1080 a few feet from the muzzle. Sometime back, Corbon supplied me with enough of their BeeSafe Pre-fragmented load for a good evaluation. These were doing high 1100s. Many lightweight pre-frags hit well below the sights but these Corbons were point on at 15 yards and performed as advertised when fired through a winter coat, plywood and grocery store beef.

Carry options

This is a recoil operated design depending on the combined mass of the slide, the recoil spring and the hammer spring to retard the rearward motion of the slide. There is no hesitation sequence built in and no temporary locking of the slide with the barrel assembly as is the case with pistols chambered for more powerful rounds. Consequently, due to the necessarily heavy recoil spring, retracting and releasing the slide can be somewhat more difficult than might be the case with another design. The pistol might also require a relatively firm grip and presentation from the shooter to insure full travel of the slide under recoil. The single malfunction I have seen with my personal PPK American was a failure to chamber while a small woman was firing the arm. The round failed to fully chamber-typical of short recoil due to insufficient mass counteracting recoil. (It responded to the “Tap” drill.]

The PPK originated the trigger action that continued with what some have called the “Second Generation” of Auto Pistols. Loading and firing sequence is as follows: Insert loaded magazine, retract the slide and release. With the frame- mounted safety in the up position, the chamber is now loaded, the hammer back in the single action mode and the pistol ready to fire. If the safety is placed in the down position prior to functioning the slide, the hammer follows the slide to rest on an internal drum holding it away from the firing pin. Additionally, the firing pin is locked against forward motion and the trigger is disengaged. Engaging the safety with the hammer at full stand drops the hammer to the safe , at-rest position as above. Pushing the safety upward engages the trigger, unlocks the firing pin and presents a cut- away in the safety drum exposing the firing pin. The pistol can now be fired with a double action pull of the trigger- or cocked for precise single action firing. Upon firing, the slide is driven back by the force of the cartridge and the empty case strikes the ejector and is flipped out of the port. The main spring drives the slide forward chambering the next round and the hammer is back for a single action shot-or de-cocking with a downward rotation of the safety. After the last round, the magazine follower engages a slide lock and the slide remains in the rearward position. Ejection of the magazine is by way of a release button on the forward left of the frame.

When hand cycling the slide, it is particularly important to keep the trigger finger outside of the trigger guard. This action requires quite a bit of strength and the pistol tends to snap forward with the closing of the slide. This can bring the careless finger in contact with the trigger and if the safety is not engaged, an inadvertent discharge will result.

When properly assembled and well maintained, the PPK can be a very reliable arm. This is a pistol that shows quite a bit of individuality from one example to another. I have seen recent examples (Pre S&W), new in the box that would not fire because of poor fitting of the trigger bar to the sear. The trigger functions intermittently or not at all and the affected guns require a quick round trip to the factory. Some examples allow the shooter to manually run rounds through the action and function with complete reliability in the dry mode. The same gun might then jam regularly under life fire. By contrast, my 1997 vintage, PPK American has never malfunctioned under live fire with me doing the shooting but the ejector /extractor geometry is so out of sync that manual function is impossible and results in double feeds. If the pistol should jam in the clinch, I would likely have to disassemble it to get it back into action.

The Stainless PPK Americans--at least those produced prior to the new association with Smith and Wesson--came factory standard with a razor sharp hammer rowel and slide rails. Upon firing, these elements would come in contact with the shooting hand drawing blood. A mini-melt job, just sufficient to dull the edges, fixes this making the gun comfortable to shoot. A persistent complaint about the PPK is that the double action trigger pull is very heavy and is not at all responsive to gunsmithing. The short hammer throw requires a strong mainspring to insure ignition of the cartridge.

Negatives aside, the PPK can be an efficient delivery system for the arguably effective .380 round. The guns are mechanically accurate. My example came with a test target showing a three round group of about 1.7” at 15 meters. At 25 yards, my five round bench groups ranged from just over two to about 4” with a variety of ball and JHP ammunition. I found that by engaging the trigger near the tip of my finger, I could make the transition from initial double action to the subsequent single action shots with no shift in point of impact. I have come to expect tight, center mass hits with reasonable speed to about 25 yards. Precise head shots are obtainable at ten to fifteen yards.

Selection of a PPK as a personal defense tool is not an estate to be entered into lightly. Ingenious design and high standards of material, fit, finish and reputation are not quite enough. The individual pistol should be carefully examined and tested. Once reliability is established, its suitability to the individual shooter becomes equally important. The shooter with sufficient hand strength to retract the slide and a firm enough grip to allow the action to function might arrive at the PPK as an intelligent alternative to the mini-mouse guns as a primary or secondary arm.

since the website crashed AUG 2003